The Sawan Gas Field was discovered by OMV in 1990 and started successful gas production in 2003. The power system of the field consisted of five 3.2 MW generators delimited to 2.6 MW and connected to the distribution system at 3.3 kV level. All generators were equipped with under and over-frequency relays with settings at ±2.5 Hz, 2.0 sec. The total plant load varied between 5.73~6.0 MW. The complete load was distributed separately in two trains serving its two consumers with six Lean Amine Pumps (0.69 MW each).

Problem

The plant at Sawan was operating with four out of five generators running, even though the load could be adequately handled by only three generators. The objective was to optimise the operation by running three generators simultaneously, which was suitable based on the load requirements at that time. However, a concern arose when one generator would trip while the other three were running, leading to under-frequency issues and potential overloading of the remaining two generators, ultimately causing blackout.

Solution

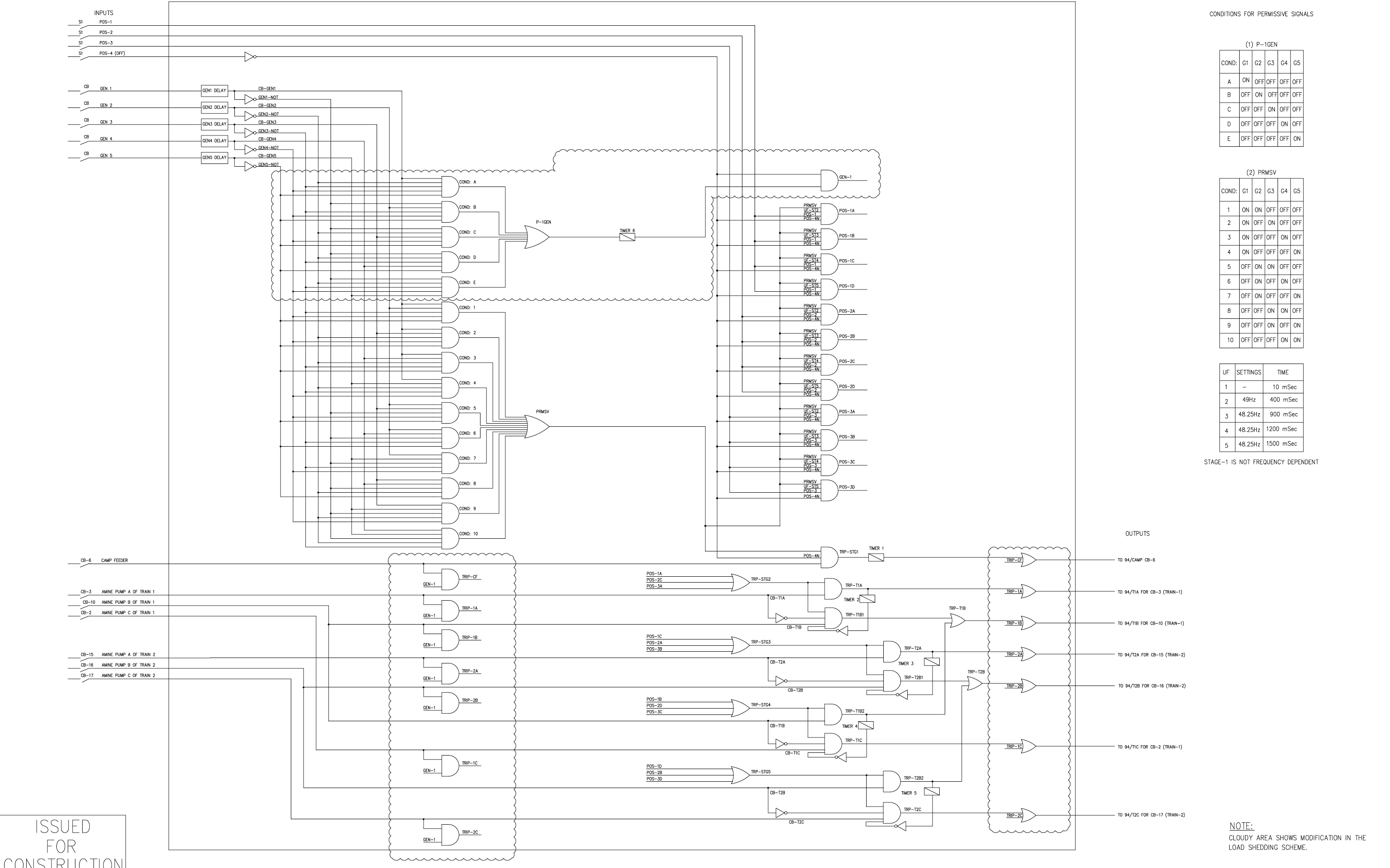

EPENAM provided a state of the art protection-grade end-to-end load shedding solution including engineering, design, manufacturing, installation, testing and commissioning. The solution was based on a load-shedding panel. The panel had a Feeder Management Relay type F35 make GE Grid Solutions, test blocks, self-reset relays, position switches, and auxiliary material. The beauty of this solution was a boolean logic of complex combinations, taken care by a custom built logic within F35’s flash memory. This served as the heart of the load shedding solution. The logic that determined the load shedding considered following:

- The underfrequency, which is a result of an overloaded generating system and which would occur when one out of the three generators trip. Scheme offered five stage underfrequency load shedding with time delays.

- To initiate the load-shedding scheme, the boolean logic would confirm the statuses of the generators. The logic would generate a permissive signal only when it confirms that two out of five generators are operational, the underfrequency is in load shedding range, and the status of the loads determined by the position of selector switch allow the load shedding.

- Additionally, the logic assessed the load distribution between Load Train-1 and Load Train-2 and chose the appropriate load to be disconnected for load shedding.

A part from above, the boolean logic would consider a load shedding only after careful evaluation of the outcomes from more than seventy boolean gates. This ensured an extremely sophisticated load shedding solution.

Conclusion

The load-shedding scheme reduced the operational cost in the range of Millions of Dollars over its life time and enabled maximum production. The implemented scheme effectively prevents the occurrence of blackouts, which has been the primary purpose behind installing the load-shedding scheme, as it takes many hours in cold start process costing millions.